Description

Performance Features:-

* The housing is made by aluminum alloy die casting with high voltage electrostatic plastic spraying on the surface

and has good anti-corrosive performance.

* Configured with an internationally renewed brand of LED light source and the ceramic substrate SMT surface

mounting process, providing good heat-conduction property and color rendering, featured with circuit ESD

electrostatic discharge design and a lifespan up to 50,000h

* Specialized constant-current power supply, wide voltage AC 85V-260V input design, featured with open circuit

protection, short-circuit protection, surge protection, lightning protection, overvoltage protection, etc.

* Borosilicate tempered glass, resistant to high-energy impact protective cover’s transmittance up to 95%

providing good lighting effect and high luminance.

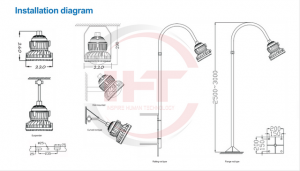

* Steel tube wiring G3/4″, multiple mounting methods optional for users, the light is provided with a mounting

bracket enabling free adjustment of the mounting angle based on requirements.

Applicable Place:-

* Widely applied in general lighting and operation lighting in hazardous environments of oil exploitation, oil refining,

metal smelting, chemicals, military, coal mines, thermal power stations, wineries, etc

* Applicable for Zone 1, Zone 2, Class IIA, Class IIB and Class IIC explosive gas environments and flammable dust

environments as well as Zone 21 and Zone 22 flammable and explosive sites.

Reviews

There are no reviews yet.